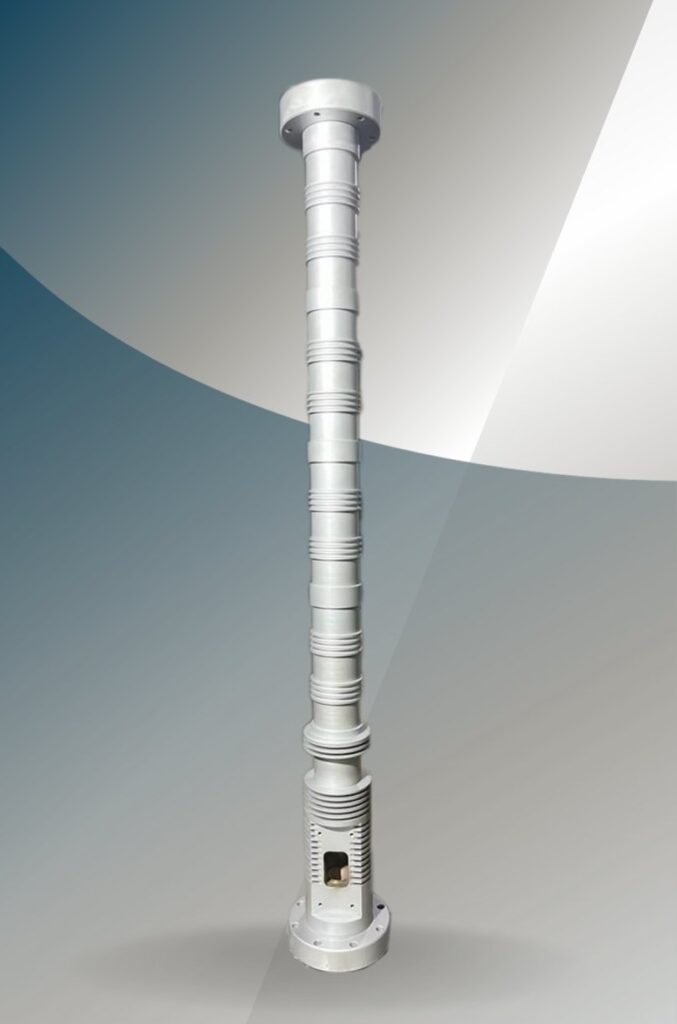

SEMI BIMETALLIC BARREL

NTP pioneer in bimetallic barrel technology, are produced to the

highest quality standards

Modal Box Title

After being in this plastic industry for more then 18 years we have seen a huge demand for bimetalic barrel from the customers who are processing polymers having glass content in it but the cost of bimetallic barrel are way more than the nitrited barrels so many customers hesitate to buy or they don’t eill to buy as the investment is so hight looking after this things, we at NTP have developed a good alternative for bimetallic (&t,30 GF) barrel and our customers around india are very much satisfied by it

In semi bimetallic process anti - wear linning in barrel is given by shrink fitting higher grade material to protect the barrel from abrasion & wear

Superior material sleeve is fitted inside the metering &: compression section of the barrel which has the hardness about 60 -65 HRC which enhances the barrel life against wear &: abrasion

Semi Bimetallic barrel is highly suitable for processing polymers containing 30 -45 % glass fibers which will give life upto 24- 30 months.

SPECIFICATIONS:

Available Size: Diameter 50.0 - 300.0MM Insert Method: Heat & Shrink fit with a certain clearance Support Material : EN-41B (Musco) Lining Material : D2 , K110 , M2 , S-600 Hardness: 62-65 HRC

Benefits

- Extended work life through the selection of the optimum alloys for the specific abrasive and wear resistance requirements

- Increased throughput and product quality through precision fit between screw and barrel for a longer period of time

- Best & Important Point of Semi-Bimetallic Barrel is that one can reuse the barrel after a certain period of time by removing the sleeve and inserting a new sleeve in it.

Applications

- High-quality proprietary backing steel for less inherent stress, and better straightness during heat cycles for the ultimate in strength and straightness.

- Not Recommended for processing PC, PMMA, PVDF, or POM Transparent Polymers.