Sliding Type Valves

The NTP sliding ring valve is designed for general purpose applications

The APV family of closure valves (R. Dray Manufacturing) utilizes a sliding closure design, requiring no fast initial velocity to close the valve. This design provides faster closure and more consistency and is suitable also for low-viscosity polymers

Benefits

- Greater durability through application-tailored materials

- Lower cost through replaceable components and low initial investment

- Greater flexibility through user selectable levels of wear performance

Applications

- Industry-standard design

- Flow path design can be tailored to a wide range of resins

- Materials of construction range from standard H13 and D2 tool steels to high-performance CPM grades

- Available in three-piece and four-piece

configurations

Castle/lock type Valves gn Plunger

The NTP castle ring valve is designed for general purpose applications

The Interlocking (or Castle) design has tabs that interlock with slots on the retainer. This requires the ring to turn with the screw, eliminating wear between the ring and the front seat. Side loading is applied to the interlocking components, making this interface critical.

Benefits

- Improved wear life in abrasive applications

- Consistent part weight

Applications

General purpose with abrasive filler

BMC Ring Plunger

The NTP sliding ring valve is designed for general-purpose applications

NTP has designed a valve that has been statistically proven to provide extremely consistent shot-toshot repeatability with many difficult to process resinss

Benefits

- Longer service life through improved

wear - Greater processing flexibility

- Better product quality through

elimination of burning and black specks - Enhanced product quality through

lower part weight deviation

Applications

RPVC

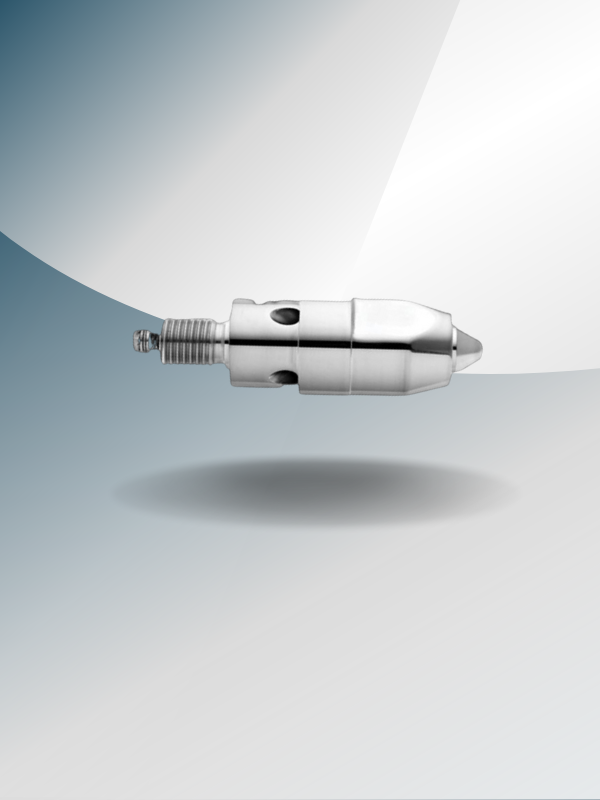

Ball check Valve

The NTP sliding ring valve is designed for general-purpose applications

There are two basic types of ball check valves: (1) Front Discharge and (2) Side Discharge, with modifications to the ball and seat sizes that determine flow rates. The body and hence the O.D. rotate with the screw and have to accept a compressive load during plasticating.

Benefits

- Superior shot repeatability

- Easy maintenance

- Low part weight deviation

- Good wear performance

- Can be rebuilt by re-seating and

installing new ball

Applications

- All polyolefin-based materials with greater than 8 MI

- Polystyrene

- LSR

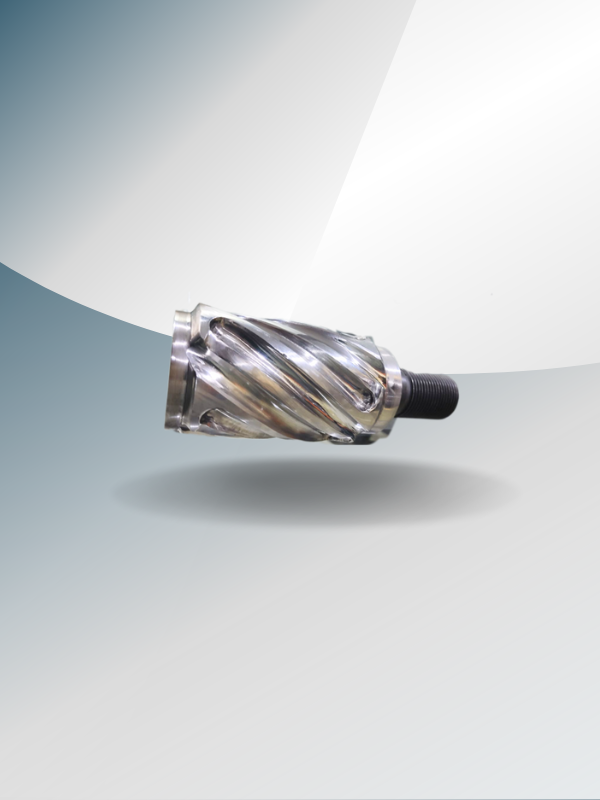

Customised Mixing Design Plunger

The CMD valve has individual replacement parts for the wear areas. The front seat can also be reversed for continued wear. The pressure drop is low and the design is streamlined. This is a design patented by CMD Corporation.

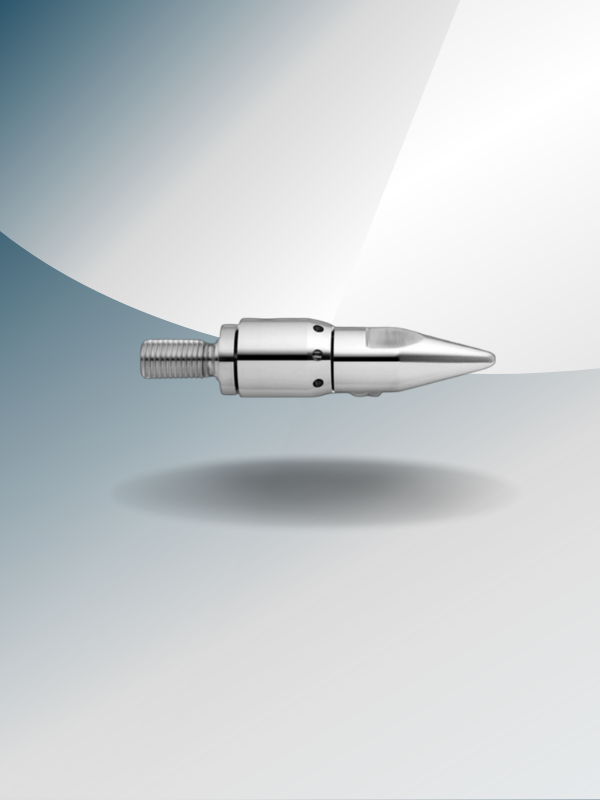

3-Piece Free Flow Valve

valve has a positive shut-off, is versatile with most all resins, and is free-flowing, yet self-cleaning. To accomplish this, we made the shut-off mechanism independent of the travel of the screw.

Benefits

- Consistent performance

- Superior shot control

- Less scrap produced

- Extended service life

- Reduced shear and black specks

Applications

- Free-flowing, positive shutoff, self-cleaning

- Most consistent shot-to-shot repeatability in the industry

- The Shut-off mechanism operates independently of screw travel