Services

- Home

- Services

Barrel screw Refurbishment

Barrel wear usually occurs in two locations. With filled materials (glass, mica, etc.), the wear starts near the end of the feed and continues through the transition section of the screw, in the middle of the barrel. With unfilled materials, the wear occurs at the discharge end where the valve reciprocates. Both types of wear can be repaired.

Modal Box Title

Barrel Inspection Process

- Inspect the inside diameter with an inside micrometer or cylinder gauge.

- Check straightness and concentricity using either an optical or bore gauge.

- Issue an inspection report as well as a quotation.

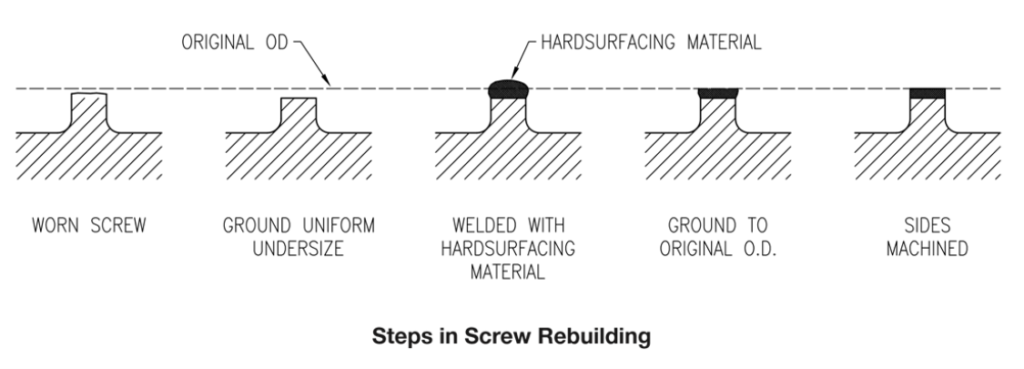

Screw Rebuilding Repair Steps

- The screw is set up in a lathe and a center is found. At this time it is also checked for straightness and concentricity.

- It is then polished and prepped for stripping off the existing chrome; the entire screw is submerged in an acid bath to remove the chrome plating.

Toggleplaten Refurbishmentt

Modal Box Title

Surfaces that are coined or not structurally sound can allow the die to flex during the fast shot, impact, and intensification.

Short-term solutions include welding and hand grinding the surface to create a flat supporting area.

Machine the platen to Re-qualify the surface using portable milling equipment.

Longer term solutions include tear down,removal,welding and Blanchard grinding.

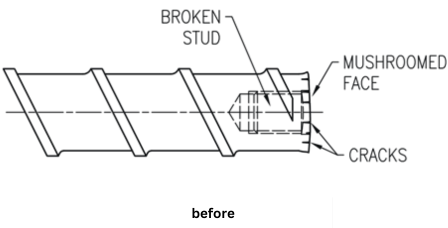

Tie-bar Rejoining

Modal Box Title

Tie-bar rejoining is one of the services offered by NTP since in injection moulding Tie-bar breakage and tie-bar thread wearing is very common issue which leads to machine breakdown production downtime which cause huge losses to the user.

For tie-bar joints we use high quality steel grade (EN-19 MUSCO) which is high in chromium and iron which ensures great durability of tiebar threads and along with the material for joining process we use some special weld electrodes which can comply with your broken tiebar and won’t create any kind of thermal distortion during or after welding.